1. Plastic Fruit Turnover Boxes

Advantages:

Lightweight and easy to carry: Plastic has a low density, reducing logistics costs for manual or mechanical handling.

Strong corrosion resistance: Resistant to fruit juices, moisture, and acid-base substances, preventing rust or deterioration for long-term fruit storage.

Good sealing and moisture resistance: Some plastic boxes have sealed lids to isolate dust and moisture, maintaining fruit freshness.

Diverse shapes and standardized specifications: Molded via injection molding into various sizes (e.g., rectangular, square) for easy stacking and transportation.

Moderate cost: Suitable for small to medium-scale fruit circulation.

Disadvantages:

Poor high-temperature resistance: Prone to deformation under high temperatures (e.g., PP withstands ~100°C, PE ~70°C), unsuitable for high-temperature storage or transport.

Limited impact resistance: Easy to crack under heavy pressure or collision, especially for low-quality plastic boxes.

Environmental concerns: Traditional plastic is non-biodegradable, causing pollution; recyclable plastics exist but have high recycling costs.

2. Wooden Fruit Turnover Boxes

Advantages:

Good air permeability: Natural wood pores promote air circulation, reducing mold growth due to moisture—ideal for respiring fruits (e.g., apples, pears).

High compressive strength: High-quality wood (e.g., pine, birch) is hard and load-bearing, suitable for stacking heavy loads without deformation.

Reusable and recyclable: Repairable when damaged, and can be disassembled for fuel or 板材 (boards), more eco-friendly than traditional plastic.

Natural texture: Used for high-end fruit transport (e.g., imported fruits) to enhance product grade.

Disadvantages:

Heavy weight: Increases transportation costs and complicates handling.

Prone to moisture and mold: Wood swells and rots when absorbing water, risking fruit hygiene.

High cost: Premium wood is expensive, and processing (cutting, sanding, anti-corrosion treatment) adds to costs, lowering cost-effectiveness vs. plastic.

3. Metal (Aluminum Alloy/Stainless Steel) Fruit Turnover Boxes

Advantages:

Extreme strength: Aluminum alloy or stainless steel resists impact and pressure, suitable for long-term, high-frequency use with a long lifespan.

Wide temperature tolerance: Stainless steel withstands -270°C to 600°C, and aluminum alloy outperforms plastic in heat resistance—ideal for cold chain or high-temperature transport.

Easy cleaning and disinfection: Smooth surfaces allow cleaning with detergents, high-pressure water, or high-temperature sterilization, meeting food hygiene standards.

Fully recyclable: Metal can be 100% recycled, reducing waste pollution.

Disadvantages:

Heavy weight and high cost: Denser than plastic or wood, increasing transport costs; stainless steel is expensive, suitable only for high-end scenarios.

Poor air permeability: Tight sealing can cause moisture buildup without proper ventilation, requiring air holes or systems.

Risk of scratching fruits: Rough edges or inner walls may damage fruit skins.

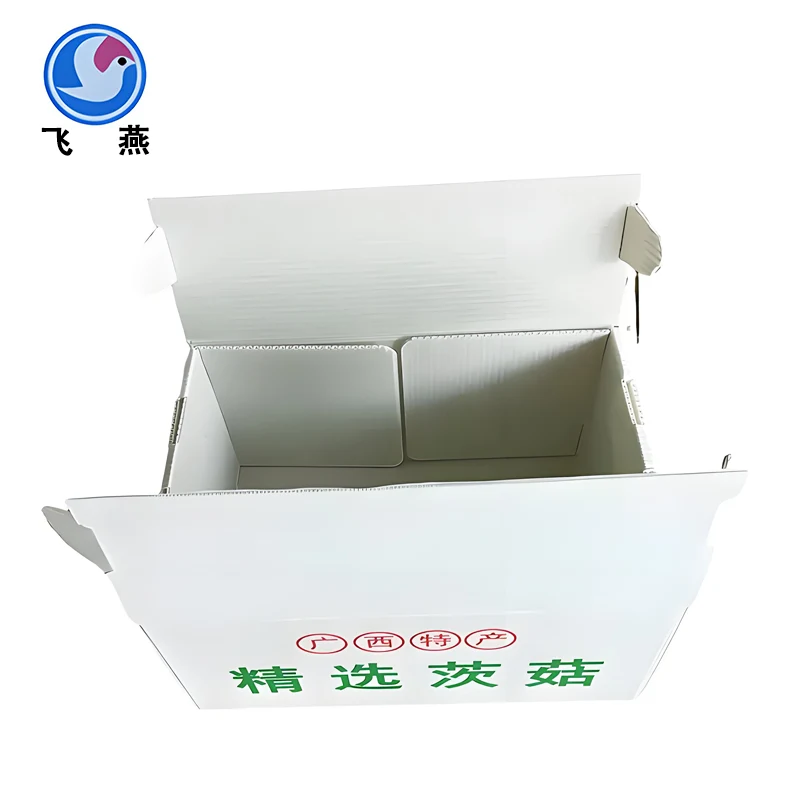

4. Corrugated Paper/Paperboard Fruit Turnover Boxes

Advantages:

Extremely low cost: Suitable for single-use (e.g., retail packaging, short-distance transport).

Lightweight and eco-friendly: Recyclable or biodegradable (e.g., degradable paper boxes), aligning with environmental trends.

Print-friendly surface: Directly print brand info or product descriptions for marketing.

Disadvantages:

Poor water resistance: Softens and breaks when wet, unsuitable for humid environments or long-distance transport.

Low load-bearing capacity: Only suitable for light fruits (e.g., strawberries, cherries) with limited stacking layers.

Short lifespan: Prone to wear after multiple transports, with higher long-term costs than reusable boxes.

5. Bamboo Fruit Turnover Boxes

Advantages:

Natural and eco-friendly: Bamboo is fast-growing and renewable, biodegradable—more sustainable than plastic.

Good air permeability and heat dissipation: Loose bamboo structure aids air circulation, ideal for cooling tropical fruits (e.g., bananas, mangoes).

Unique texture: Natural aesthetic for high-end fruit packaging or gift boxes.

Disadvantages:

Prone to cracking and deformation: Bamboo shrinks and cracks with humidity, lacking long-term stability.

Relatively heavy: Heavier than plastic, reducing handling convenience.

High processing cost: Requires manual cutting, sanding, and anti-insect/anti-corrosion treatment, costing more than plastic.

6. Comparison Table of Materials

MaterialAdvantagesDisadvantagesSuitable Scenarios

Plastic Lightweight, corrosion-resistant, cost-effective, standardized specs Poor heat resistance, easy to crack, environmental concerns Daily fruit wholesale, supermarket distribution, short-term storage

Wooden Good air permeability, high compressive strength, recyclable Heavy, prone to moisture, high cost, quarantine needed High-end fruit transport, bulk fruits requiring ventilation (e.g., apples, pears)

Metal (Aluminum/Stainless Steel) High strength, wide temperature tolerance, easy to clean, recyclable Heavy, expensive, poor air permeability Cold chain transport, high-frequency use, high food hygiene requirements

Corrugated Paper/Paperboard Low cost, lightweight, eco-friendly, printable Poor water resistance, low load-bearing, single-use Fruit retail packaging, short-distance transport, e-commerce express packaging

Bamboo Natural, eco-friendly, good air permeability, unique texture Prone to cracking, relatively heavy, high processing cost Specialty fruit packaging, gift boxes, eco-friendly short-term use

Selection Tips

Short-term transport or retail: Prioritize plastic or paper boxes for cost and convenience.

Long-distance transport or freshness preservation: Choose wooden boxes or plastic boxes with ventilation designs.

High-frequency recycling: Opt for metal or high-quality plastic boxes for durability.

Environmental needs: Use degradable plastic, wooden, or bamboo boxes.

High-end fruits or gift packaging: Select wooden, bamboo, or customized metal boxes to enhance value.